Please visit our Demonstration Database to explore the many Estimator’s Buddy features. This DB functions identically to a production Buddy site, including extensive validation of user input. The Demo Projects reflect various applications, including diverse Piping and Equipment (Boilers, Vessels, Hoppers, Ducts, eg). Demo users are notified of the success of their change simulations, as no changes to the Demonstration Database are allowed. Registered users may change their own Projects freely, no notice necessary.

The Estimator’s Buddy is actually two systems, Piping and Equipment. Takeoff input forms conform to Internet standards, and user entries are subject to extensive validation, to maintain system integrity. ‘Help’ is provided at key points. User input is fast and easy.

The Estimator’s Buddy is actually two systems, Piping and Equipment. Takeoff input forms conform to Internet standards, and user entries are subject to extensive validation, to maintain system integrity. ‘Help’ is provided at key points. User input is fast and easy.

Project Form

Identifiers

A unique Project Number will be required upon Project addition. The other fields in the top section are optional, for reference purposes. Be sure to enter dates in the format shown.

Jobsite Conditions

These required entries will all affect both Production and Support rates. Be aware that Weather factors are cumulative. Supervision and Labor assessments are based on National averages, and may be varied by the user to analyze differences. Wage is an hourly average of all trades, including per diem and expenses. Overtime Rate reflects a Labor Union presence.

Vendor Discounts

Clients utilizing Custom Materials are typically offered volume discounts by their vendor. These are maintained here.

Table Pipe Insulation

Our table prices cover all sizes you may encounter. Custom Materials are often not available in larger Industrial sizes covered by our Table prices. Simply enter price specifications for one prominent size of each material used, and our tables will extrapolite all other sizes’ cost.

Table Pipe Jacket

Used when Table Jacket types specified.

Table Prefab Jacket Elbows

Largely deprecated, this fallback specification remains mandatory.

Measure Method

This required entry is crucial in accounting for Elbow footages. Users of Digitizers/CAD Systems will likely select Center-to-Center, whereas Manual Takeoffs may require the Weld-to-Weld method.

Additional Line Items

Provided for your convenience.

Piping

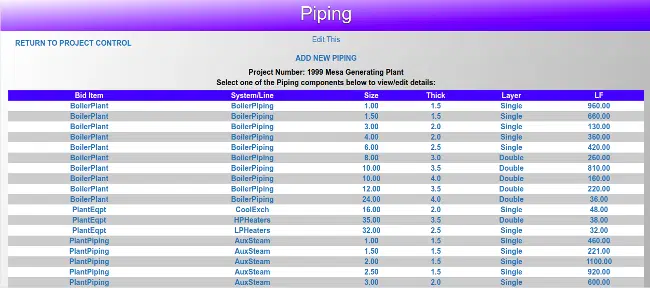

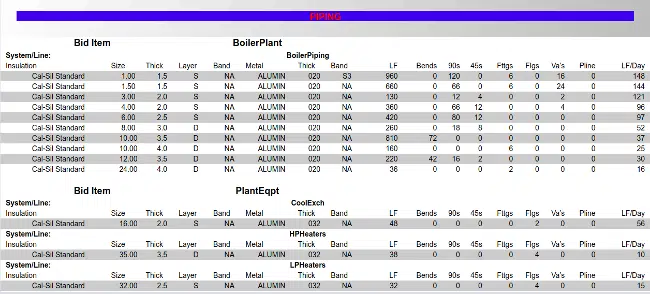

Piping Table

For reporting purposes, Piping components are organized with Bid Item as the major category, and Line/System within that, further delineated by Size and Thickness.

A Power Plant may dictate an organization utilizing a Process System such as Main Steam or Boiler Piping as the Bid Item, and specific Line Numbers as System/Line. A Refinery could require Geographic Area (N-21, eg) as the Bid Item, and line segments as System/Line. Digital drawings could relocate the Line Number to Bid Item, and the Drawing Number to System/Line.

The flexibility of this organization will accommodate any Project requirements.

A Power Plant may dictate an organization utilizing a Process System such as Main Steam or Boiler Piping as the Bid Item, and specific Line Numbers as System/Line. A Refinery could require Geographic Area (N-21, eg) as the Bid Item, and line segments as System/Line. Digital drawings could relocate the Line Number to Bid Item, and the Drawing Number to System/Line.

The flexibility of this organization will accommodate any Project requirements.

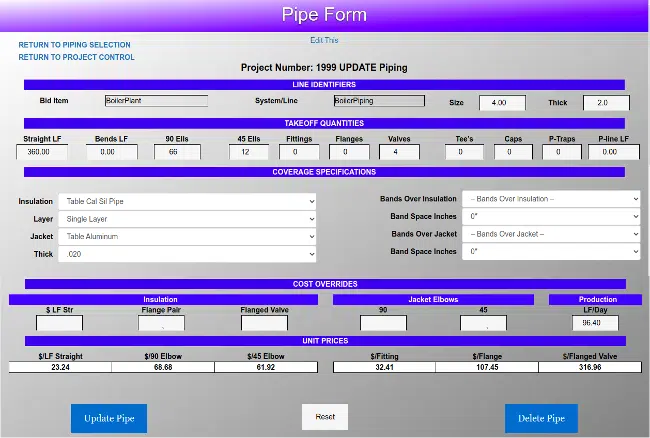

Pipe Form

This screen facilitates individual Piping component addition and maintenance. Categorized by Bid Item and Line/System, these elememts are retained from one addition to the next, to facilitate rapid takeoff input. Previous entries are available, for consistency, and new items are easily added.

Takeoff Quantities are simple, with one exception: Fittings. Defined as “any custom cut” not otherwise specified, these cover a wide range: Cutouts for hangers, pipe supports, reducers, and steam tracing, are all examples of Fittings.

Coverage Specifications detail the Insulation, Jacket, and Band requirements for this Component. These will be retained from one addition to the next, to facilitate speed of takeoff entry. We offer several Custom Materials, in addition to our Table materials. For a nominal fee, we will convert your vendor’s tables and assimilate them into our database.

When Cost Overrides indicate the inclusion of Removable wraps, the appropriate Labor adjustments are made.

Unit Prices will prove invaluable when quoting accurate Changes and Additions, as well as billing for unspecified Field Changes and other chargeable items. Materials, Labor, Application, and Support are all apportioned into each attachment’s Unit Price.

Takeoff Quantities are simple, with one exception: Fittings. Defined as “any custom cut” not otherwise specified, these cover a wide range: Cutouts for hangers, pipe supports, reducers, and steam tracing, are all examples of Fittings.

Coverage Specifications detail the Insulation, Jacket, and Band requirements for this Component. These will be retained from one addition to the next, to facilitate speed of takeoff entry. We offer several Custom Materials, in addition to our Table materials. For a nominal fee, we will convert your vendor’s tables and assimilate them into our database.

When Cost Overrides indicate the inclusion of Removable wraps, the appropriate Labor adjustments are made.

Unit Prices will prove invaluable when quoting accurate Changes and Additions, as well as billing for unspecified Field Changes and other chargeable items. Materials, Labor, Application, and Support are all apportioned into each attachment’s Unit Price.

Flatwork

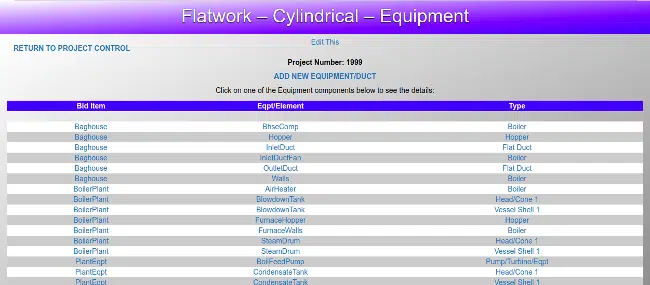

Flatwork-Cylindrical-Equipment Table

Similar to Piping, Flatwork, Cylindrical Components, and Equipment are categorized by Bid Item as the major grouping element, and Eqpt/Element a subcategory within that, for reporting purposes. A Bid Item may contain both Piping and Equipment.

EQUIPMENT TYPES Covered:

- Boiler

- Hopper

- Flat Duct

- Round Duct

- Expansion Joint

- Head

- Cone

- Pump

- Vessel

- Turbine

- Fan

- Other Equipment

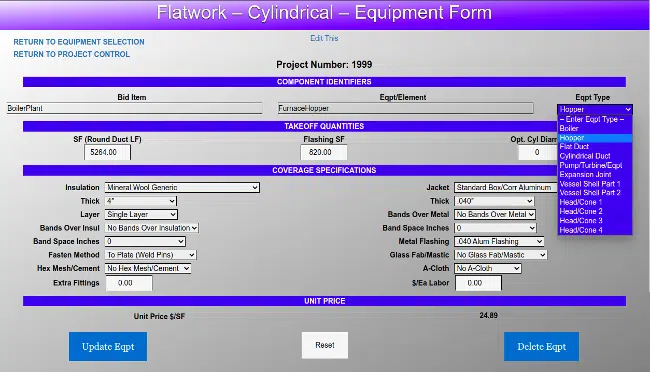

Flatwork-Cylindrical-Equipment Form

Within Piping, Size and Thickness further delineate a System/Line, whereas within Flatwork, Eqpt Type is used to further define Eqpt/Element. As an example, a Vessel or Tank may specify more than one coverage, under a walkway, for instance. It may contain up to four Heads or Cones, each treated differently. The dropdown menu in the screenshot to the left lists the Equipment Types we cover.

Takeoff Quantities within Equipment are typically Square Feet. The sole exceptiion is Round Ducts, which are measured in Linear Feet. Opt. Cyl Diameter applies when using oversize Curved Sidewall covering.

Due to the wide variety of Flatwork-Cylindrical-Equipment Components, there are more special treatments and configurations available than with Piping. Our Coverage Specifications are intended to cover most contingincies. Great lengths are taken to assure that each Eqpt Type is appropriately treated.

An all-inclusive Unit Price is provided, to assist when quoting Changes and Additions.

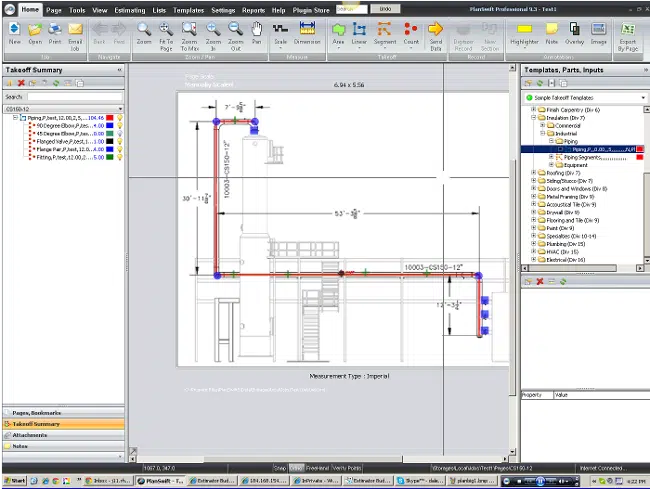

Digitizers

FastBuddy

If you use a CAD System or Digitizer, you are in luck! FastBuddy will make fast work of your Piping takeoff. Simply point-and-click your drawings into memory, upload the whole batch to your Estimator’s Buddy, and we convert your takeoff into Buddy input within microseconds! Leave the lists and the keyboard behind.

Every digitizer is capable of Custom Takeoff templates. The Estimator’s Buddy interface captures the following:

- Bid Item

- System/Line

- Size

- Thickness

- Straight Pipe LF

- Bends LF

- 90° Elbows

- 45° Elbows

- Fittings

- Flanges

- Flanged Valves

- Tee’s

- Caps

- P-Traps

- Pipeline LF

FastBuddy clients enjoy an additional Upload Piping Spreadsheet option on their Pipe Form, to upload the Excel spreadsheet produced by their Digitizer to the Buddy System for further processing. A companion Spreadsheet Specifications option is added to their custom menu, to supply the coverage details for that particular spreadsheet, including Insulation, Jacket and Band specifications.

We contact new FastBuddy users immediately, to arrange development of their individual interface, as most digitizers vary somewhat in their Excel format, and each must be tailored to the SQL format which The Estimator’s Buddy utilizes. We simply adapt our templates to the instant spreadsheet. Typically this can be accomplished within one week, usually much sooner.

We contact new FastBuddy users immediately, to arrange development of their individual interface, as most digitizers vary somewhat in their Excel format, and each must be tailored to the SQL format which The Estimator’s Buddy utilizes. We simply adapt our templates to the instant spreadsheet. Typically this can be accomplished within one week, usually much sooner.

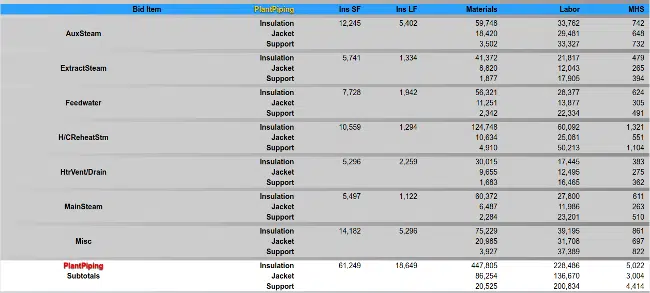

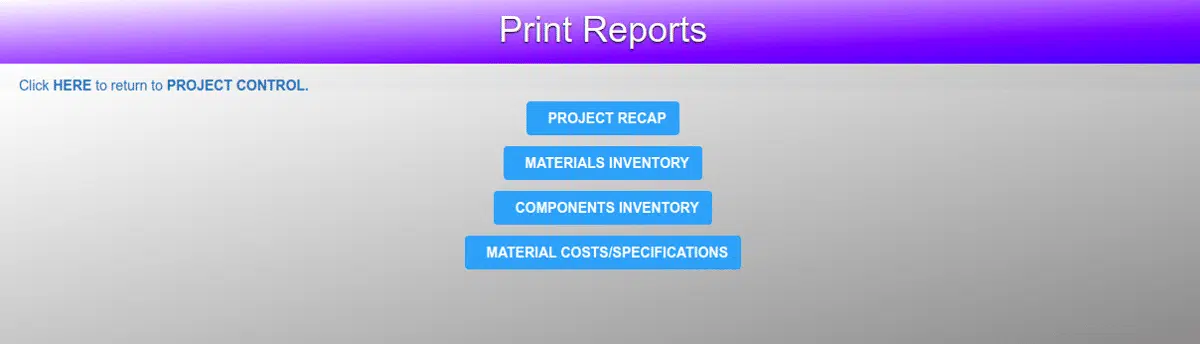

A complete, real-time set of Reports is generated each time the user selects Calculate Projections – Produce Reports from their Project Control menu. These Reports are time-stamped with a time of compilation, and only valid as a Matched Set. Should a factor in one Report change, it could potentially affect other Reports.

The four Reports, in combination, provide all of the information necessary to prepare an accurate, detailed, and successful Bid Proposal.

The four Reports, in combination, provide all of the information necessary to prepare an accurate, detailed, and successful Bid Proposal.

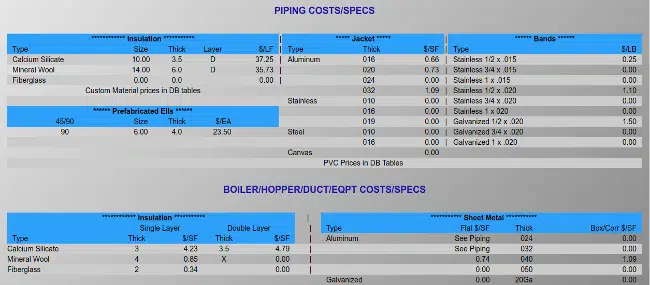

Costs and Specifications

This Report details all Costs and Specifications pertaining to this Project at the time of compilation. In addition to the Table Material prices shown, this Report also displays all Project Identifiers, Jobsite Conditions, Custom Material Discounts, Measure Method and Miscellaneous Costs.

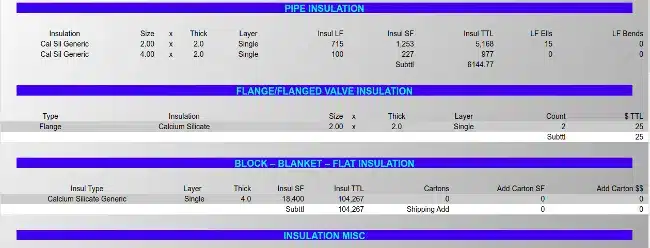

Materials Inventory

This Report lists all Materials required for this Project.

Components Inventory

This Report lists Project Components, including all Piping, Flatwork/Cylindrical and Equipment. All coverages are shown, including Band requirements, Attachment Method as necessary, and Custom Treatments (Hex Mesh, Glass Fab, Cement, eg). Piping detail includes all attachments and characteristics (Elbows, Flanges, Valves, Tee’s, P-Traps, Fittings eg.

Bid Recap

The Bid Recap represents the culmination of many factors, including adjustmants for Weather, Labor, and Project Type, among others. Our exclusive Production Rates have been applied to all Components, to assure accurate Labor projections.

Reporting is categorized by Bid Item, and Sysem/Line within that. Both Materials and Labor costs are reported, for Insulation, Jacket, and Support.

Support Labor includes non-application costs such as Material Movement, Scaffold Erection, Administration, and Cleanup, among others.

Support Materials include Jobsite Trailer, Vehicles, Tools, Material Storage and Supplies.

Reporting is categorized by Bid Item, and Sysem/Line within that. Both Materials and Labor costs are reported, for Insulation, Jacket, and Support.

Support Labor includes non-application costs such as Material Movement, Scaffold Erection, Administration, and Cleanup, among others.

Support Materials include Jobsite Trailer, Vehicles, Tools, Material Storage and Supplies.